How to Repair and Maintain Turbocharged Engines: For Every Skill Level

Turbocharged engines are like the rockstars of the automotive world—high-performance, powerful, and capable of delivering that exhilarating rush of speed that every car enthusiast craves. But with great power comes great responsibility. If you own a turbocharged engine, you already know that it requires a bit more TLC than your average engine. Whether you’re a seasoned gearhead or a newbie just getting your hands dirty, understanding how to repair and maintain your turbocharged engine is crucial to keeping it running smoothly and efficiently.

This guide will walk you through the essentials of turbocharged engine maintenance and repair, with steps that cater to all levels of expertise. So, grab your tools, put on your work gloves, and let’s dive in!

Understanding the Turbocharged Engine: The Basics

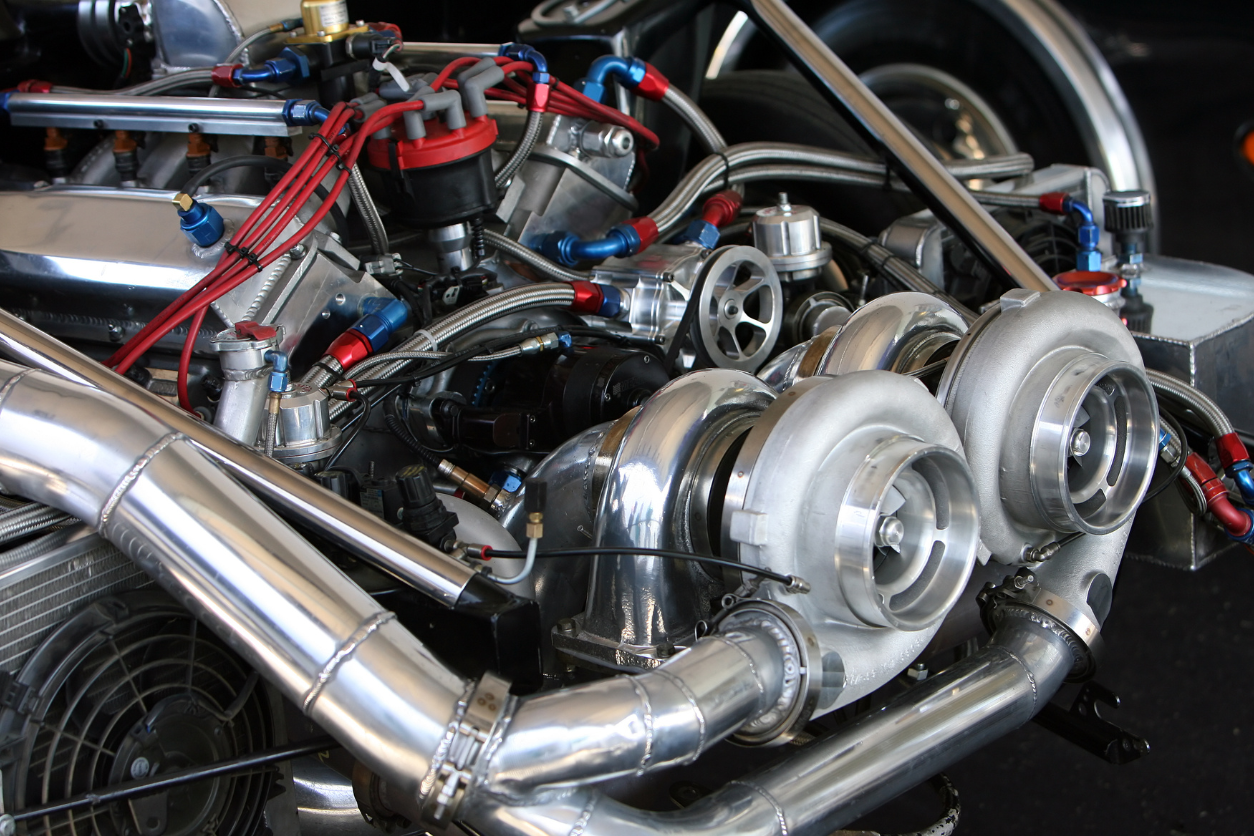

Before we jump into the nitty-gritty of maintenance and repairs, let’s get a basic understanding of how a turbocharged engine works. In simple terms, a turbocharger increases the engine’s efficiency and power output by forcing more air (and consequently more fuel) into the combustion chamber. This extra air allows the engine to burn more fuel, producing more power. The turbocharger is driven by exhaust gases, making it an essential part of your engine’s performance.

Now that you’ve got the basics down, let’s talk maintenance.

Regular Maintenance: The Key to Longevity

The best way to avoid costly repairs is through regular maintenance. Just like you wouldn’t skip a dentist appointment if you want to keep your teeth healthy, you shouldn’t skip these maintenance steps if you want your turbocharged engine to run smoothly.

1. Regular Oil Changes

Oil is the lifeblood of any engine, but it’s especially critical for turbocharged engines. The turbo spins at incredibly high speeds (up to 200,000 RPM), generating a lot of heat. Fresh, clean oil helps to lubricate the turbocharger and dissipate heat. Dirty or old oil can lead to poor lubrication, increased friction, and eventually, turbo failure.

How to Do It:

- Step 1: Warm up the engine. This helps the oil flow out more easily.

- Step 2: Use a jack to lift the car and secure it with jack stands.

- Step 3: Place a drain pan under the oil pan, remove the drain plug, and let the oil drain out completely.

- Step 4: Replace the oil filter with a new one.

- Step 5: Reinstall the drain plug, fill the engine with the recommended oil, and check the level with the dipstick.

Pro Tip: Change your oil every 3,000 to 5,000 miles, or according to your vehicle’s manufacturer recommendations.

2. Air Filter Maintenance

Your turbocharged engine breathes through the air filter, and a clogged or dirty filter can starve it of the oxygen it needs to perform. A dirty air filter can also allow debris to enter the engine, potentially damaging the turbocharger.

How to Do It:

- Step 1: Locate the air filter housing, usually found near the front of the engine bay.

- Step 2: Open the housing by removing the clips or screws.

- Step 3: Take out the old air filter and inspect it. If it’s dirty, replace it with a new one.

- Step 4: Reassemble the housing and ensure it’s sealed properly.

Pro Tip: Check your air filter every 10,000 miles, or more frequently if you drive in dusty conditions.

3. Coolant Check and Replacement

Turbochargers generate a lot of heat, and the coolant system plays a crucial role in keeping things cool. Over time, coolant can break down or become contaminated, which can lead to overheating and damage to your turbo.

How to Do It:

- Step 1: Wait for the engine to cool completely before opening the radiator cap.

- Step 2: Check the coolant level in the overflow tank. If it’s low, top it off with the recommended coolant.

- Step 3: If the coolant looks rusty or dirty, it’s time to drain and replace it.

- Step 4: Locate the drain plug on the radiator, place a drain pan underneath, and let the old coolant drain out.

- Step 5: Refill the radiator with fresh coolant, following your car’s specific requirements.

Pro Tip: Flush and replace your coolant every 30,000 miles or according to your vehicle’s service schedule.

Troubleshooting and Basic Repairs

Even with regular maintenance, issues can arise. Here’s how to tackle some common turbocharged engine problems.

1. Boost Pressure Issues

If your engine isn’t delivering the expected boost, it could be due to a leak in the intake or exhaust, a faulty boost controller, or even a damaged turbocharger.

How to Diagnose:

- Step 1: Start by checking for leaks in the intake system. Listen for hissing sounds, which can indicate escaping air.

- Step 2: Inspect all the hoses connected to the turbocharger for cracks, loose connections, or wear.

- Step 3: Use a boost gauge to check if the engine is achieving the correct boost levels. Compare this with the manufacturer’s specifications.

How to Fix:

- Step 1: If you find a leaking hose, replace it with a new one that matches your engine’s specifications.

- Step 2: Tighten any loose connections and recheck the boost levels.

Pro Tip: If the issue persists, it might be time to consult a professional or consider a turbo rebuild.

2. Turbocharger Smoke Issues

If you notice smoke coming from the exhaust, especially blue or black smoke, it could indicate an issue with the turbocharger’s oil seals or a rich fuel mixture.

How to Diagnose:

- Step 1: Check the color of the smoke. Blue smoke usually indicates burning oil, while black smoke suggests an overly rich fuel mixture.

- Step 2: Inspect the turbocharger for oil leaks. Look around the seals and connections.

How to Fix:

- Step 1: If the seals are leaking, you might need to replace them. This can be a complex task, so if you’re not confident, it’s best to seek professional help.

- Step 2: If the smoke is black, check the air filter and fuel injectors. A clogged air filter or malfunctioning injectors can cause a rich mixture.

Pro Tip: Regularly monitor your engine’s performance and address any smoke issues immediately to prevent further damage.

3. Turbo Lag

Turbo lag is that frustrating delay between hitting the gas pedal and feeling the turbocharger kick in. While some lag is normal, excessive lag can indicate a problem.

How to Diagnose:

- Step 1: Pay attention to the lag time. Is it longer than usual?

- Step 2: Inspect the turbocharger for any signs of wear, especially in the bearings and turbine.

How to Fix:

- Step 1: Clean the turbocharger’s components. Sometimes, carbon build-up can cause lag.

- Step 2: Check the wastegate for proper operation. A malfunctioning wastegate can cause lag by not regulating boost pressure correctly.

Pro Tip: If cleaning doesn’t improve the lag, it may be time to consider upgrading your turbo or components for better performance.

Advanced Maintenance: For the Gearheads

If you’re comfortable with more advanced maintenance, consider these tasks to keep your turbocharged engine in top shape.

1. Intercooler Maintenance

The intercooler helps cool the air compressed by the turbocharger before it enters the engine, improving efficiency and power. Over time, the intercooler can become clogged with debris or oil, reducing its effectiveness.

How to Do It:

- Step 1: Remove the intercooler from the engine bay (this might require removing some surrounding components).

- Step 2: Inspect the fins for dirt, debris, or oil.

- Step 3: Clean the intercooler using a degreaser and rinse it thoroughly with water. Allow it to dry completely before reinstalling.

2. Turbocharger Rebuild

If your turbocharger is showing signs of wear, such as excessive play in the shaft or damage to the compressor wheel, a rebuild might be necessary.

How to Do It:

- Step 1: Disassemble the turbocharger, carefully noting the position of each part.

- Step 2: Inspect each component for wear and damage.

- Step 3: Replace any worn parts with new ones, ensuring that everything is balanced and properly aligned.

- Step 4: Reassemble the turbocharger and reinstall it in the engine.

Pro Tip: Rebuilding a turbocharger requires precision and specialized tools. If you’re not experienced with this type of work, consider sending the turbo to a professional rebuilder.

Final Thoughts: Keep Your Turbo Running Strong

Maintaining and repairing a turbocharged engine might seem daunting, but with the right approach, it’s absolutely manageable, regardless of your skill level. Regular maintenance is your best defense against costly repairs, while a bit of DIY knowledge can help you troubleshoot and fix common issues. And remember, when in doubt, don’t hesitate to consult with a professional. Your turbocharged engine is a high-performance machine, and keeping it in top shape will ensure that you continue to enjoy those thrilling drives for years to come. So, get under the hood, get your hands dirty, and give your turbo the care it deserves. Happy wrenching!